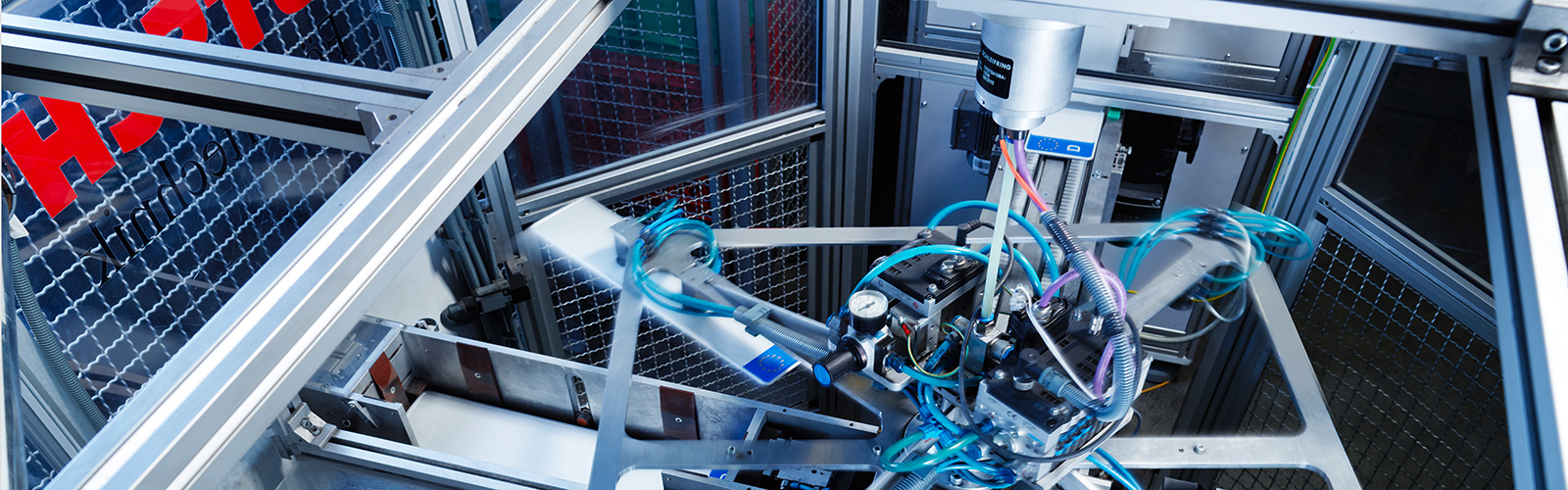

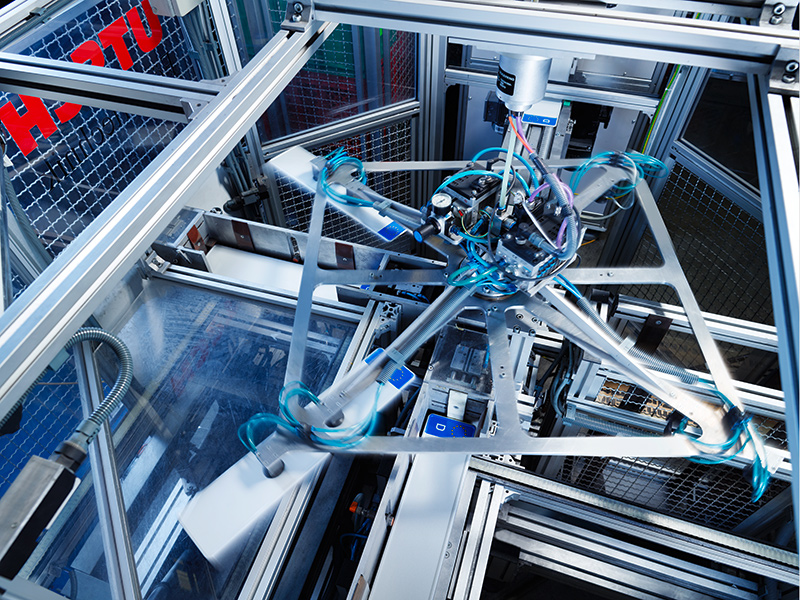

Fully automatic machines

Made-to-measure, fully automatic machines and systems from UTSCH make it possible to produce blanks and finished license plates reliably, economically and on a large scale with minimal staff.

Please contact us for details

Mr. Christoph Wäschenbach

Product Engineering

Head of Mechanical & Tool Construction

- Phone + 49 (0) 271 / 3191-175

- Fax + 49 (0) 271 / 3191-23-175

Mr. Thomas Wollenweber

Product Engineering

Head of E-Construction

- Phone + 49 (0) 271 / 3191-179

- Fax + 49 (0) 271 / 3191-23-179

English

English

Deutsch

Deutsch

Español

Español

Français

Français